Wind Power

Wind energy (or wind power) describes the process by which wind is used to generate electricity. Wind turbines convert the kinetic energy in the wind into mechanical power. A generator can convert mechanical power into electricity. Mechanical power can also be utilized directly for specific tasks such as pumping water.

Wind is caused by the uneven heating of the atmosphere by the sun, variations in the earth's surface, and rotation of the earth. Mountains, bodies of water, and vegetation all influence wind flow patterns. Wind turbines convert the energy in wind to electricity by rotating propeller-like blades around a rotor. The rotor turns the drive shaft, which turns an electric generator. Three key factors affect the amount of energy a turbine can harness from the wind: wind speed, air density, and swept area.

Wind Farm Development

Siting a wind farm varies from one location to another, but there are some important matters for land owners to consider:

Understand your wind resource

Evaluate distance from existing transmission lines

Determine benefits of and barriers to allowing your land to be developed

Establish access to capital

Identify reliable power purchaser or market

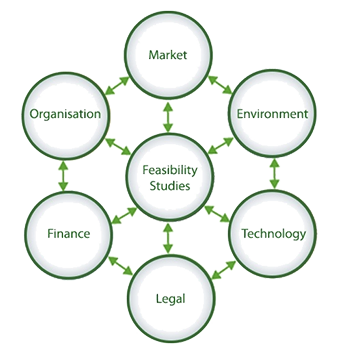

Address siting and project feasibility considerations

Understand wind energy’s economics

Obtain zoning and permitting expertise

Establish dialogue with turbine manufacturers and project developers

Secure agreement to meet O&M needs

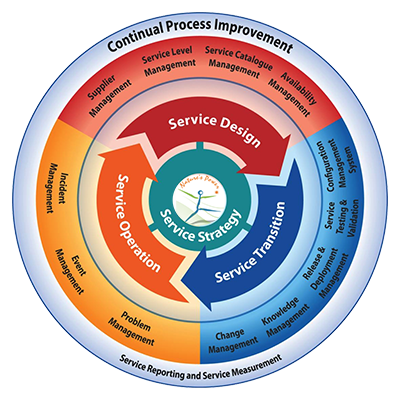

Necessary Services to Avail

Wind power project or WPP involves development through own resources and manpower or by availing the technical services from consultant organisations:

SITE IDENTIFICATION: The process starts with regional overviews and precision GIS mapping, through which the specific opportunities are determined at a feasible site. This also involves mapping of project boundaries, turbine micro-siting and optimisation.

WIND RESOURCE ASSESSMENT: Accurate Wind Resource Assessment of a widely variable resource is the most critical feature for success of a WPP. Meso-Scale and then Micro-Scale Wind Power Density/Wind Speed Map is produced for the site location through input of accurate contour/terrain data. Ideal spot is selected to install Anemometry System. The recorded wind data is critically analyzed and formatted to represent wind characteristics. A preliminary wind resource assessment can be carried out by using the freely available Global Wind Atlas.

MICRO-SITING & ENERGY ESTIMATION: This constitutes the foundation of a Wind Power Project. Wind Resource data is formatted in terms of Speed and direction. The characteristic power of selected Wind Electric Generator (WEG) is formatted. Detailed Contour data at close interval is prepared indicating roughness and terrain features. WEG layout is optimised and Micro-siting Map is prepared using software and then estimated is energy generation.

DETAILED PROJECT REPORT: Once the site, make and rating of WEG and the selling option are finalized, detailed survey and field study is conducted. Comprehensive layout design is prepared with optimization of generation along with detailed design for approach road and grid evacuation. Detailed costing and financial analysis is carried out to establish overall viability.

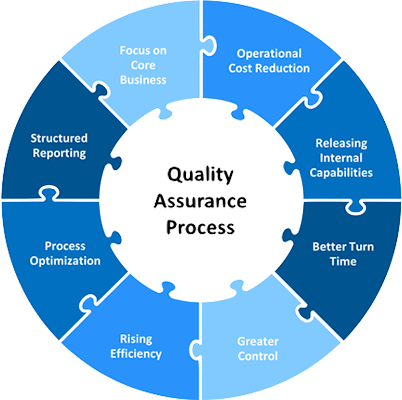

PROJECT MANAGEMENT: Implementation and Management of Wind power project, WPP, calls for Multi-disciplinary activities related to Technical, Financial and Commercial aspects. Not only quality of works needs to be checked, it is equally important to ensure close co-ordination and monitoring for timely commissioning.

MONITORING: Energy generation with respect to wind resource, frequency and type of machine and system failures needs to be critically monitored and analyzed to optimize generation. Income from WPP can be optimized only if break down and failure of WEG and evacuation system is avoided particularly during the limited high wind months.

PERFORMANCE IMPROVEMENT: For the existing Wind Power projects also there is often need to ensure its performance improvement, which goes down with time. Critical analysis of monitoring reports along with on-site observations and in depth study immensely help in performance improvement through reduction in break-down time and interval losses. Due to seasonal availability of wind resource, generation increasing in cubic proportion of wind speed and overall low Plant Load Factor, parameter setting and operational/control logic needs to be site specific.

LENDER'S ENGINEERS: To meet the need of expert engineers to serve a project especially for a definite term or contract, where the task may not be managed with the available resources, the clients are provided Lenders Engineer’s services as per the requirements assessed mutually with the client. This involves serving through deputing or appointing suitable personnel and thus meeting the need of the project at a given point of time of various technical types.

Land Requirements

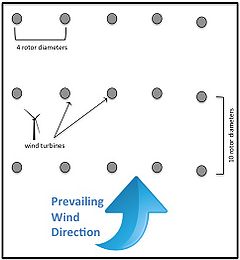

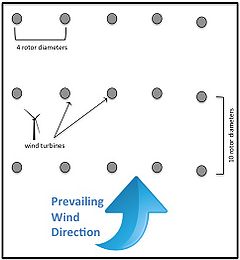

The amount of land required for a wind farm varies considerably, and is particularly dependent on two key factors: the desired size of the wind farm (which can be defined either by installed capacity or the number of turbines) and the characteristics of the local terrain[14]. Typically, wind turbine spacing is determined by the rotor diameter and local wind conditions. Some estimates suggest spacing turbines between 5 and 10 rotor diameters apart. If prevailing winds are generally from the same direction, turbines may be installed 3 or 4 rotor diameters apart (in the direction perpendicular to the prevailing winds); under multi-directional wind conditions, spacing of between 5 and 7 rotor diameters is recommended.

SSEV WIND

Each wind farm is unique, with a set of very specific local challenges that go well beyond immediate technical issues, such as choosing the appropriate technology.

For a wind farm to be successful it needs to provide an attractive commercial return, be expertly designed to make the most of the local wind resource, connect effectively to the grid and integrate with the electricity market, and satisfy important environmental and community considerations.

SSEV draws on more than 10 years of experience at the forefront of the industry developing and delivering wind farms in India. Around the world, we have been involved in more than 10 advanced and operational wind farms.

Our team can guide you through the full spectrum of activities in developing, constructing, commissioning, operating, and upgrading your wind farm. We are increasingly called upon for smart integration of hybrid renewable energy generation, such as adding solar and battery storage into new or existing wind farms to optimise the generation profile or to provide frequency control ancillary services (FCAS). And for long-term storage, clients are turning to us for site selection and feasibility of pumped hydro energy storage.

Our guidance extends well beyond a purely technical consultancy. Due to our unique asset-ownership experience, we can offer you the benefit of our insights and experiences of negotiating major contracts and agreements, working with legal and commercial service providers, and supplying specialised technical services for EPC contractors.

We have also worked closely with investors to help them make informed decisions when investing in renewables and have assisted developers seeking project financing by preparing bankable yield estimations.

Our services include:

pre-feasibility and feasibility studies.

resource monitoring and data collection.

resource assessments and energy estimates.

GIS and spatial solutions.

wind turbine technology assessments.

community consultation.

planning permits and environmental impact assessments.

power system studies and grid connection compliance testing.

balance of plant design.

reactive power and voltage control design.

optimisation of operations.

options studies.

technical due diligence.

advisory services to prospective investors.

owner’s engineer services.

ECI and EPC design.

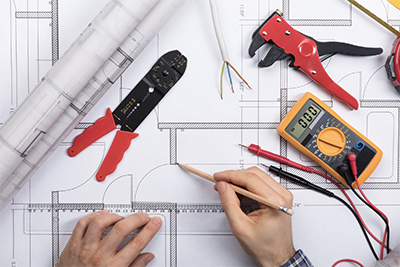

DC Side Single line diagrams.

DC Side Single line diagrams.

SSEV’s technical due diligence service supports owners and investors during acquisitions or any other transaction involving a change of ownership.

SSEV’s technical due diligence service supports owners and investors during acquisitions or any other transaction involving a change of ownership.  Pre-financial closure phase (Technical & Commercial due diligence)

Pre-financial closure phase (Technical & Commercial due diligence)

warranty follow-ups and all other relevant activities of the project. Keeping owners fully informed, we are always focused on maximizing your investment returns.

warranty follow-ups and all other relevant activities of the project. Keeping owners fully informed, we are always focused on maximizing your investment returns.

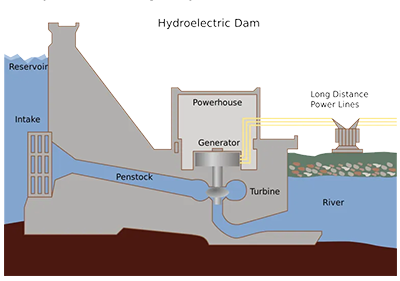

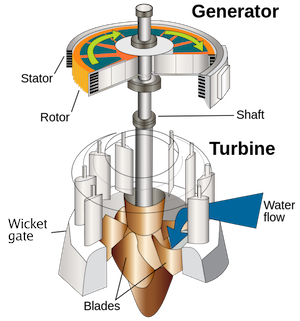

Hydroelectric power (hydro) is classed as a renewable energy due to the fact that it relies on the Earth’s natural water cycle's kinetic energy to generate electricity. With its 90% efficiency in converting the kinetic energy to electricity, and the fact that no fuels are burnt and no direct emissions are released into the atmosphere, it is often considered as a very clean form of electricity generation.

Hydroelectric power (hydro) is classed as a renewable energy due to the fact that it relies on the Earth’s natural water cycle's kinetic energy to generate electricity. With its 90% efficiency in converting the kinetic energy to electricity, and the fact that no fuels are burnt and no direct emissions are released into the atmosphere, it is often considered as a very clean form of electricity generation.

The amount of land required for a wind farm varies considerably, and is particularly dependent on two key factors: the desired size of the wind farm (which can be defined either by installed capacity or the number of turbines) and the characteristics of the local terrain[14]. Typically, wind turbine spacing is determined by the rotor diameter and local wind conditions. Some estimates suggest spacing turbines between 5 and 10 rotor diameters apart. If prevailing winds are generally from the same direction, turbines may be installed 3 or 4 rotor diameters apart (in the direction perpendicular to the prevailing winds); under multi-directional wind conditions, spacing of between 5 and 7 rotor diameters is recommended.

The amount of land required for a wind farm varies considerably, and is particularly dependent on two key factors: the desired size of the wind farm (which can be defined either by installed capacity or the number of turbines) and the characteristics of the local terrain[14]. Typically, wind turbine spacing is determined by the rotor diameter and local wind conditions. Some estimates suggest spacing turbines between 5 and 10 rotor diameters apart. If prevailing winds are generally from the same direction, turbines may be installed 3 or 4 rotor diameters apart (in the direction perpendicular to the prevailing winds); under multi-directional wind conditions, spacing of between 5 and 7 rotor diameters is recommended.

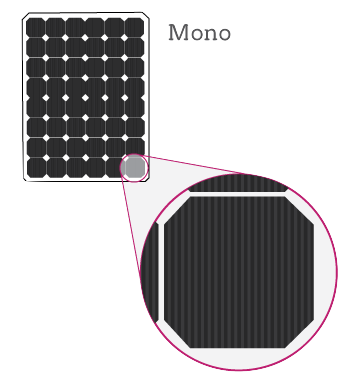

Mono-crystalline solar PV cells are produced from a single crystal of silicon (grown from highly pure molten silicon). This crystal is then cut into thin wafers between 0.2mm and 0.3mm thick, which then form the basis of the solar PV cell. These solar PV cells are the most efficient, however, they also tend to be the most expensive to produce. They are rigid and are mounted in a rigid frame for protection.

Mono-crystalline solar PV cells are produced from a single crystal of silicon (grown from highly pure molten silicon). This crystal is then cut into thin wafers between 0.2mm and 0.3mm thick, which then form the basis of the solar PV cell. These solar PV cells are the most efficient, however, they also tend to be the most expensive to produce. They are rigid and are mounted in a rigid frame for protection.

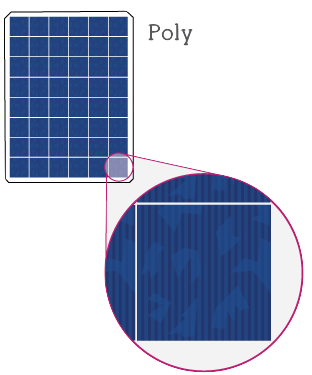

Polycrystalline solar PV cells are made from a slice cut from a block of silicon, but unlike mono-crystalline solar PV cells, polycrystalline solar PV cells contain multiple silicon crystals. This gives them a blue marbled appearance (rather than the much darker color of mono-crystalline solar PV cells). Polycrystalline solar PV cells are slightly less efficient than mono-crystalline cells; however, they are also less expensive to produce .These solar PV cells also need to be stored in a rigid protective frame.

Polycrystalline solar PV cells are made from a slice cut from a block of silicon, but unlike mono-crystalline solar PV cells, polycrystalline solar PV cells contain multiple silicon crystals. This gives them a blue marbled appearance (rather than the much darker color of mono-crystalline solar PV cells). Polycrystalline solar PV cells are slightly less efficient than mono-crystalline cells; however, they are also less expensive to produce .These solar PV cells also need to be stored in a rigid protective frame.

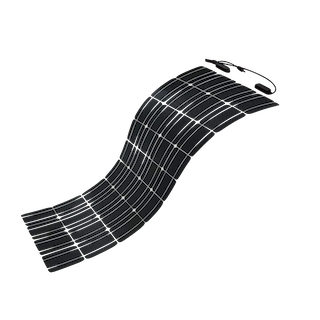

Amorphous or Thin Film Solar PV Cells Amorphous solar PV cells are a type of ‘thin film solar cells’ and are made from a thin film of amorphous (non-crystalline) silicon. This can be placed on a wide range of different surfaces and, because the amorphous silicon layer is flexible, if placed on a flexible surface, then the whole solar PV cell can be flexible. These panels are the least expensive to produce but are also the least efficient. When buying amorphous solar PV cells, you should be aware that a characteristic of this type of solar PV cell is that the power output decreases over time – typically the largest decrease is in the first few months, after which the power output stabilizes. This means that the quoted power output of amorphous solar PV cells should always refer to the maximum power after this stabilization.

Amorphous or Thin Film Solar PV Cells Amorphous solar PV cells are a type of ‘thin film solar cells’ and are made from a thin film of amorphous (non-crystalline) silicon. This can be placed on a wide range of different surfaces and, because the amorphous silicon layer is flexible, if placed on a flexible surface, then the whole solar PV cell can be flexible. These panels are the least expensive to produce but are also the least efficient. When buying amorphous solar PV cells, you should be aware that a characteristic of this type of solar PV cell is that the power output decreases over time – typically the largest decrease is in the first few months, after which the power output stabilizes. This means that the quoted power output of amorphous solar PV cells should always refer to the maximum power after this stabilization.

Our product will take the waste as intake by providing scientific way of waste disposal system and provide you Free Gas and Free Organic manure. Our products are totally environmental friendly and will help the society in many aspects like healthy and scientific disposal of kitchen waste, providing free gas and organic fertilizer etc.,

Our product will take the waste as intake by providing scientific way of waste disposal system and provide you Free Gas and Free Organic manure. Our products are totally environmental friendly and will help the society in many aspects like healthy and scientific disposal of kitchen waste, providing free gas and organic fertilizer etc.,